Concepts, Plane, Scale, Visualisation Aerial Concepts Belgium, Patric Dietvorst, Eflite, P-47D, Thunderbolt, Vallejo

These washes from Vallejo come in medium size 35ml Bottles. There are 12 different colors. For this model I have used 505 (Light Rust), 515 (Light Grey) 517 (Dark Grey), 519 (Olive Green), 521 (Oiled Earth). They are water-based and so thin with water. The wash itself is made with an acrylic resin so that the surface tension of the wash behaves like a solvent-based material, but it has the benefits of clean-up and dilution with simple water. The wash itself dries in around 15-20 minutes depending on the temperature and humidity of where you are working with them. You can also layer washes on top of each other as well. You could suffer some light deterioration of the original coat of paint.

I started with the panel lines. With a small paint, the 517 and brush carefully fill only the panel line. Let 2-3 minutes drying, then use a cloth to wipe away some wash. Wipe carefully in the direction of the panel lines. The idea is, less weathering is better and you can always add some more in a second layer.

The second step is washing the olive green surfaces. With a brush paint the 519 and apply this wash on the surfaces. After 30 to 60 seconds wipe most of the wash gentle with a cloth. Repeat if you like more wash. In the middle part of bigger areas, you best remove more to get a lighter effect. If the wash is to dry to remove use a little water or isopropyl alcohol to remove more. On the lighter surfaces at the bottom of the plane use the 515 wash with the same technique.

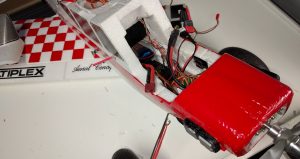

The third step is to add some details like dark gun strips (517), rust areas, add some chipping with silver acyl paint. Most details you do not wipe with a cloth. Just apply a little and let it dry.

The fourth step is to paint some elements, like paint the machine guns silver, and dry brush the motor part behind the propeller with some silver strips. You can paint the cowl internally black. I have added I yellow tape inside the front of the cowl and use some varnish to fix the tape.

Fifth step. If you finish the weathering and you are satisfied with the result, you can apply a clear varnish by aerosol. Do not overdo because this only adding weight to your model.